Tap in Struts and other complicated work pieces from M3 upto M130.

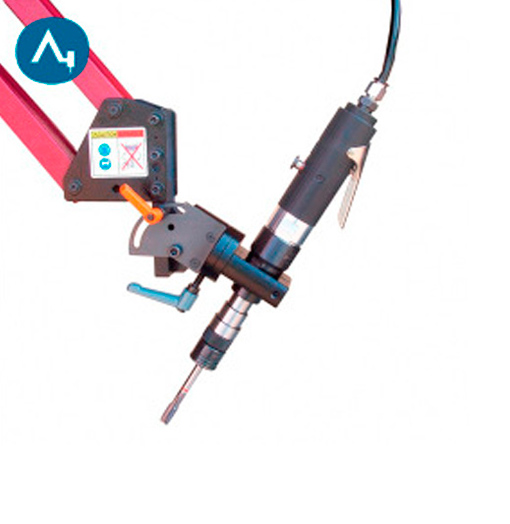

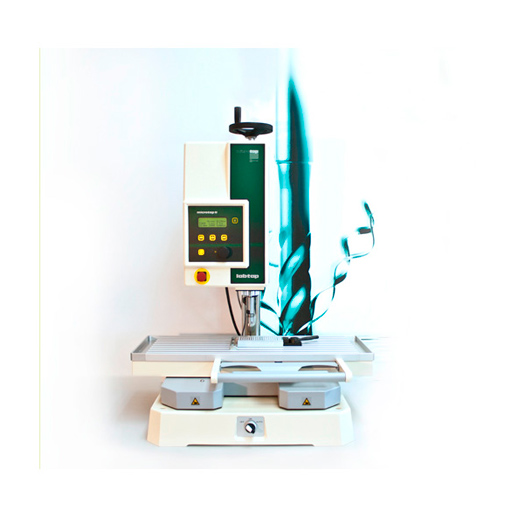

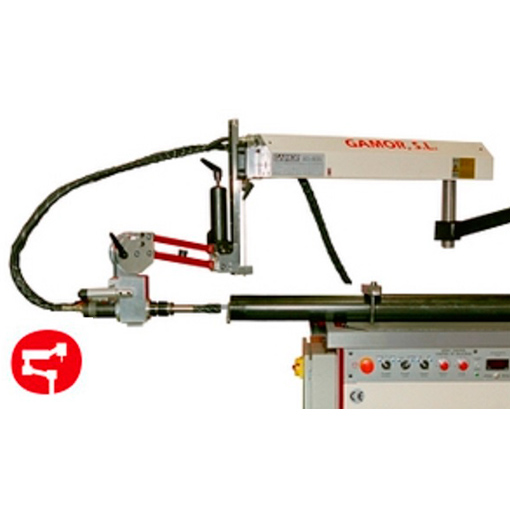

The machine is like the model Vitoria RHG-M130 (M3-M130) but with specific Options for thread cutting in struts or similar complicated parts.

EQUIPMENT

TAPPING MACHINE WITH HYDRAULIC TENSIONER, EXTERNAL COOLING AND DISCHARGE CHIP CONVEYOR (HYDRAULIC POWER PACK WITH 2 MOTORS)

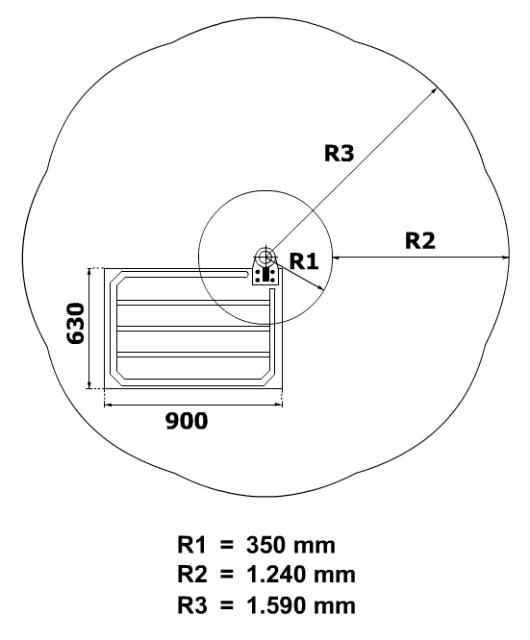

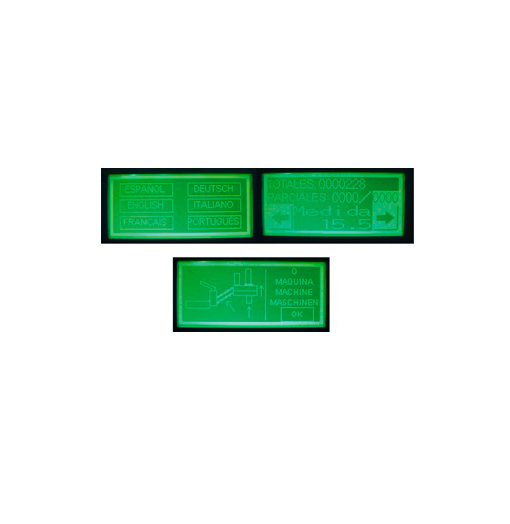

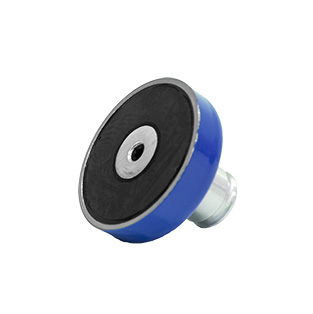

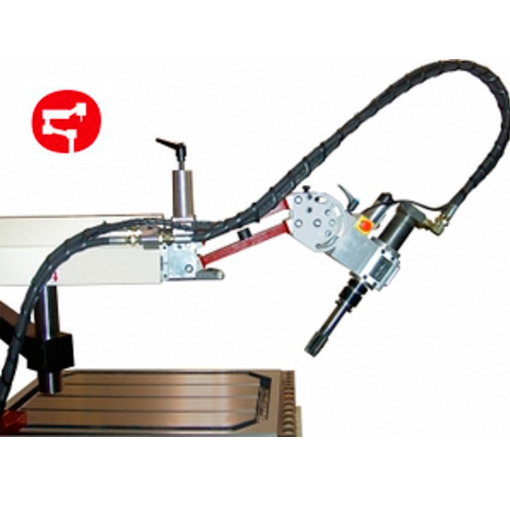

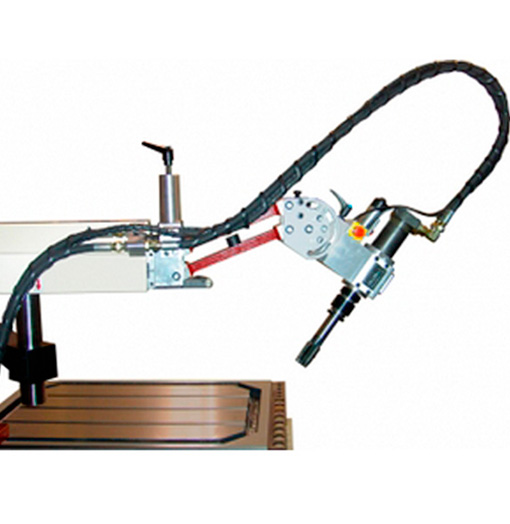

Tapping head with reduction gear, guide arm with 4 slide bars in SKF bearings, cast iron table 1200x800mm with T-slots, solid side table 90º 800x600mm, Hydraulic group with 2 electric motors, hydraulic motor, hydraulic lifting column frequence variator for speed control, tapping security system, digital revolution display RPM, hydraulic pressure control knob, hydraulic pressure manometer, gauge safety rotary knob, tool holder 60mm, oil temperature gauge, oil level indicator, Silemblock leveling jacks, Mechanical depth detector, external tool cooling system with two pumps and extra fluid cooler, chip conveyor with coolant pump and dump ton, hydraulic vise with two jaws.

GAMOR HYDRAULIC TAPPING MACHINE M2-M30 Sistema métrico: M3-M60 KG/MM²: 120 BRINELL: 352 ROCKWELL HRC: 37 METRIC: M2-M30 INCHES: BSW 3/32 - 1" 1/8 BSP 1/16 - 1" 1/8 CAPACITY: M2-M30 R.P.M.: 22 a 630 MAXIMUM PRESSURE: 140 Kg /cm² MOTOR 3 PS / 2.2KW VOLTAGE 400V-III-50HZ SPEED CONTROL: ELECTRONIC SLIDING BARS LENGTH: 750 mm TABLE WORKAREA: TOTAL QUICK CHANGE CHUCK: Nº 2 31mm OIL TANK: 50 LITROS WEIGHT: 450 Kg

GAMOR HYDRAULIC TAPPING MACHINE M2-M30 Sistema métrico: M3-M60 KG/MM²: 120 BRINELL: 352 ROCKWELL HRC: 37 METRIC: M2-M30 INCHES: BSW 3/32 - 1" 1/8 BSP 1/16 - 1" 1/8 CAPACITY: M2-M30 R.P.M.: 22 a 630 MAXIMUM PRESSURE: 140 Kg /cm² MOTOR 3 PS / 2.2KW VOLTAGE 400V-III-50HZ SPEED CONTROL: ELECTRONIC SLIDING BARS LENGTH: 750 mm TABLE WORKAREA: TOTAL QUICK CHANGE CHUCK: Nº 2 31mm OIL TANK: 50 LITROS WEIGHT: 450 Kg