GAMOR

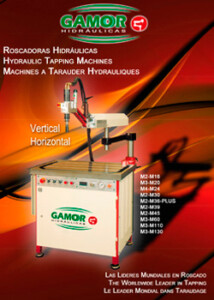

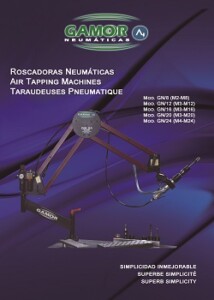

Talleres GAMOR, S.L. offers to its clients products of contrasted quality and precision all over the world.

Located in the region of the river Oria, in the village Asteasu (Guipúzcoa), flanked by mountains in the valley of the prior river mouth, the company Talleres GAMOR, S.L. managed to adapt itself to the changes that the metal mechanic industry experienced within the last 35 years.

What began as small company created by its founder Angel Benito, dedicated exclusively to the manufacturing of jaws for chucks, grew and expanded all over the national market, and became the modern, agile and effective company it is today.