MT-M30 (M2-M30)

GAMOR HYDRAULIC TAPPING MACHINE M2-M30

Sistema métrico: M3-M60

KG/MM²: 120

BRINELL: 352

ROCKWELL HRC: 37

METRIC: M2-M30

INCHES: BSW 3/32 - 1" 1/8

BSP 1/16 - 1" 1/8

CAPACITY: M2-M30

R.P.M.: 22 a 630

MAXIMUM PRESSURE: 140 Kg /cm²

MOTOR 3 PS / 2.2KW

VOLTAGE 400V-III-50HZ

SPEED CONTROL: ELECTRONIC

SLIDING BARS LENGTH: 750 mm

TABLE WORKAREA: TOTAL

QUICK CHANGE CHUCK: Nº 2 31mm

OIL TANK: 50 LITROS

WEIGHT: 450 Kg

SERIAL EQUIPMENT

[/fusion_checklist]

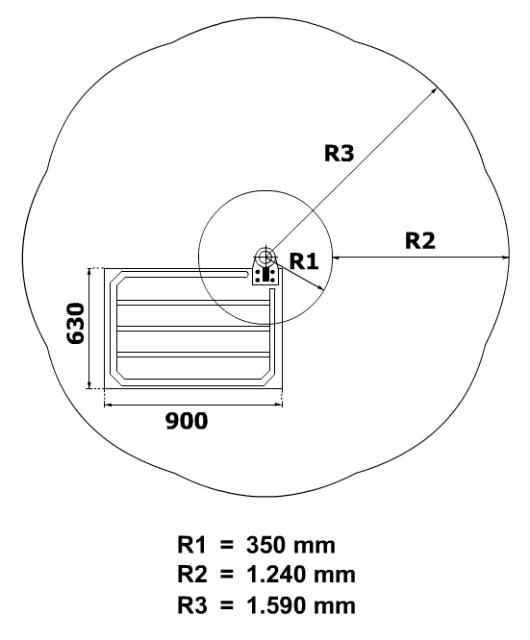

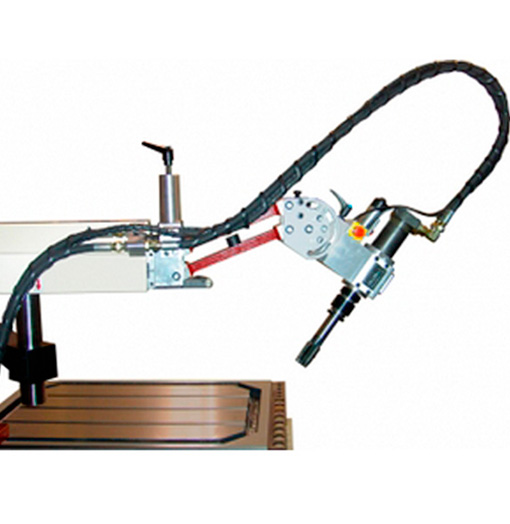

ARTICULATED ARM: 3 BARS

T-SLOT TABLE: 900 X 630 m

DIGITAL SPEED INDICATOR (R.P.M.)

COMPLETE HYDRAULIC GROUP

TAP-HOLDER SIDE SHELF

PRESSURE MANOMETER PROTECTION KEY

HYDRAULIC PRESSURE REGULATION GAUGE

POSITIONING DEVICE FOR HORIZONTAL TAPPING

GAMOR HYDRAULIC TAPPING MACHINE M2-M30 Sistema métrico: M3-M60 KG/MM²: 120 BRINELL: 352 ROCKWELL HRC: 37 METRIC: M2-M30 INCHES: BSW 3/32 - 1" 1/8 BSP 1/16 - 1" 1/8 CAPACITY: M2-M30 R.P.M.: 22 a 630 MAXIMUM PRESSURE: 140 Kg /cm² MOTOR 3 PS / 2.2KW VOLTAGE 400V-III-50HZ SPEED CONTROL: ELECTRONIC SLIDING BARS LENGTH: 750 mm TABLE WORKAREA: TOTAL QUICK CHANGE CHUCK: Nº 2 31mm OIL TANK: 50 LITROS WEIGHT: 450 Kg

GAMOR HYDRAULIC TAPPING MACHINE M2-M30 Sistema métrico: M3-M60 KG/MM²: 120 BRINELL: 352 ROCKWELL HRC: 37 METRIC: M2-M30 INCHES: BSW 3/32 - 1" 1/8 BSP 1/16 - 1" 1/8 CAPACITY: M2-M30 R.P.M.: 22 a 630 MAXIMUM PRESSURE: 140 Kg /cm² MOTOR 3 PS / 2.2KW VOLTAGE 400V-III-50HZ SPEED CONTROL: ELECTRONIC SLIDING BARS LENGTH: 750 mm TABLE WORKAREA: TOTAL QUICK CHANGE CHUCK: Nº 2 31mm OIL TANK: 50 LITROS WEIGHT: 450 Kg