-

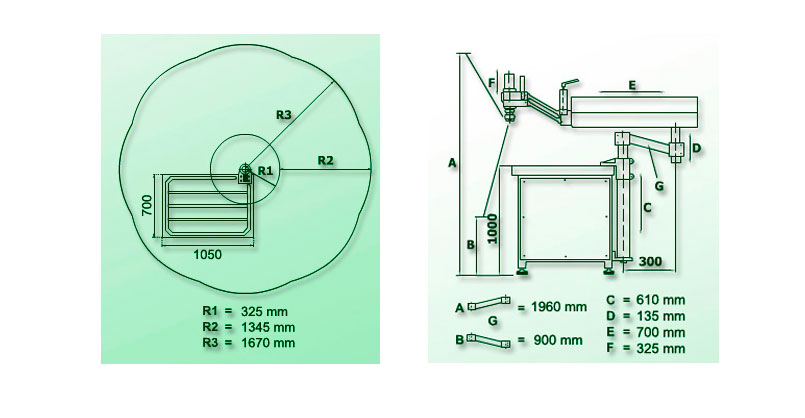

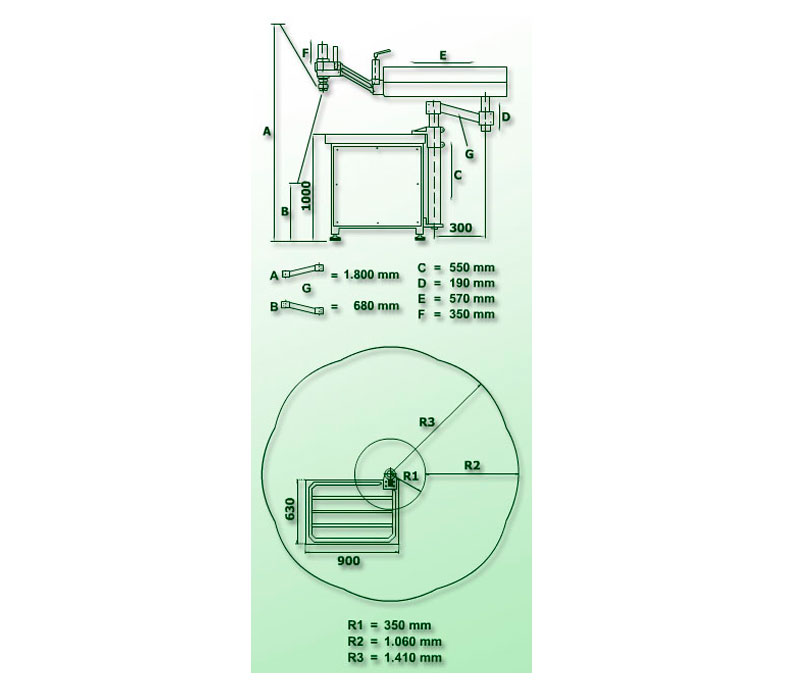

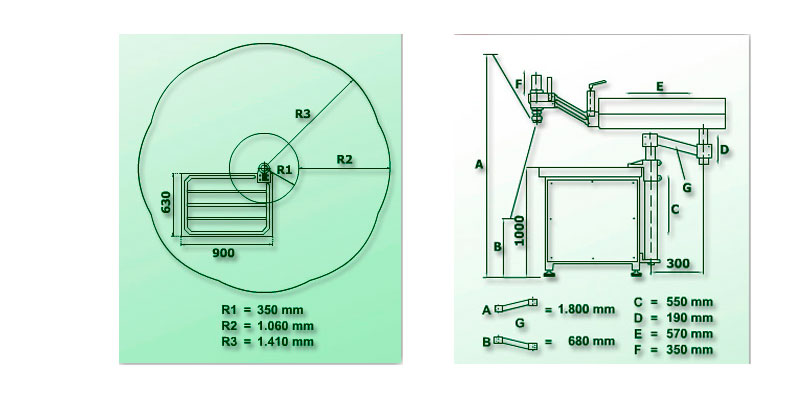

GAMOR HYDRAULIC TAPPING MACHINE RHG-M39 (M2-M39)

GAMOR HYDRAULIC TAPPING MACHINE RHG-M39 (M2-M39)THREADING CAPACITY:

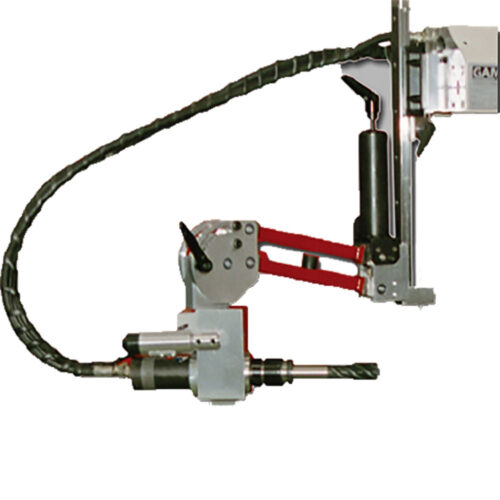

This model is specially indicated for large productions of vertical tapping, accurate mechanics, moulds and/or parts requiring a high accuracy in the execution of the tapping, with a full quality guarantee both in the finish and tapping tolerances. The machine head allows to place standard tool directly up to measures of 30 mm. It is necessary to work with a special chuck adapter from Gamor for bigger size. This special tap-holder fits in the chuck machine and can be used for sizes up to 36×29 mm.

-

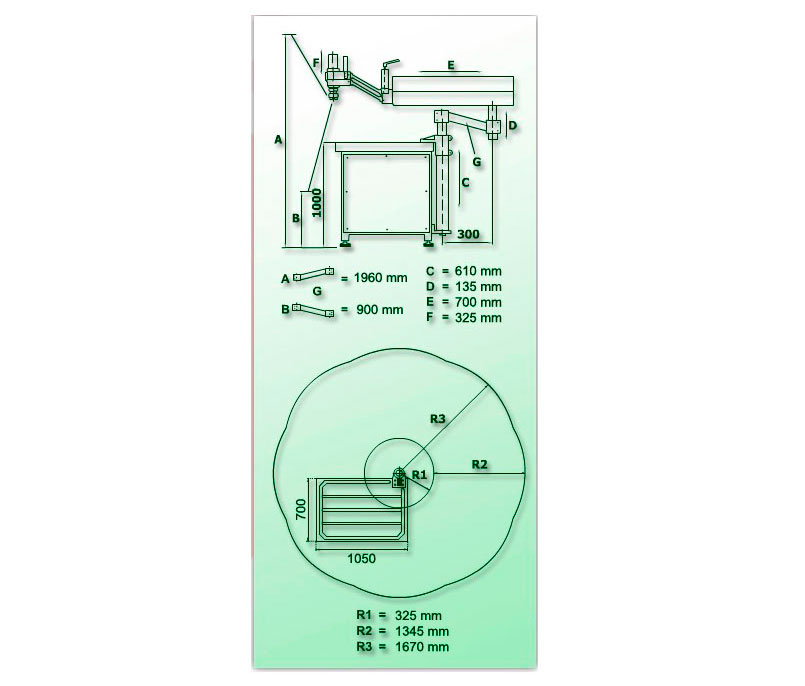

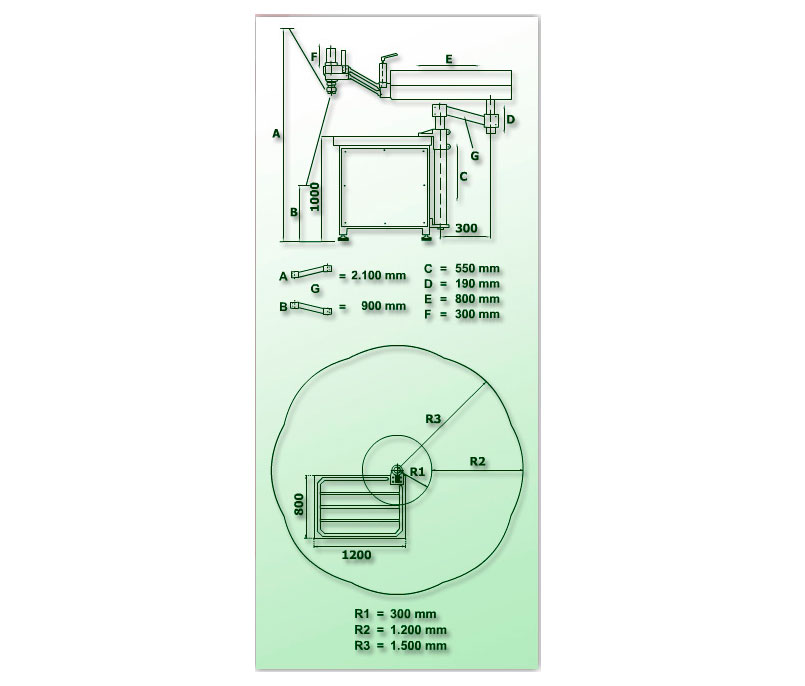

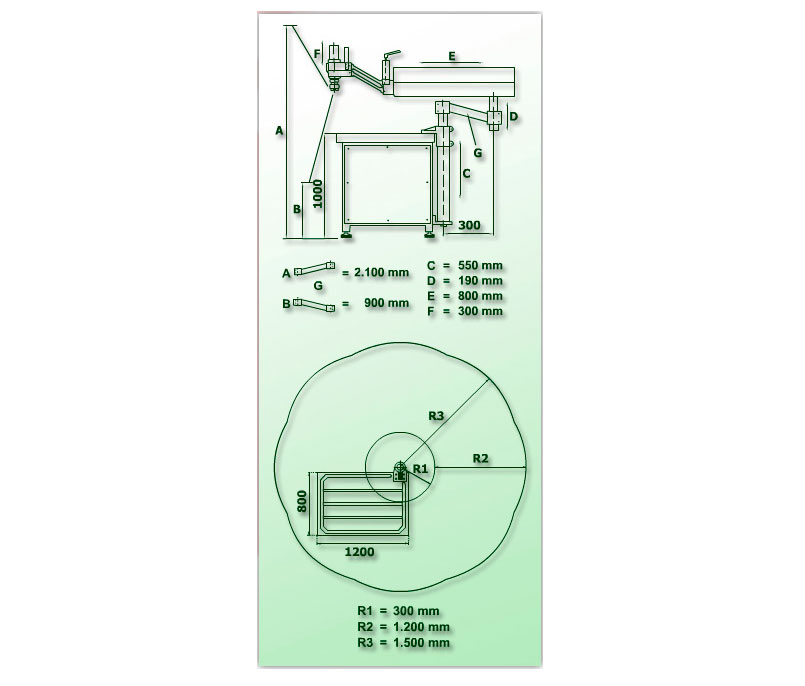

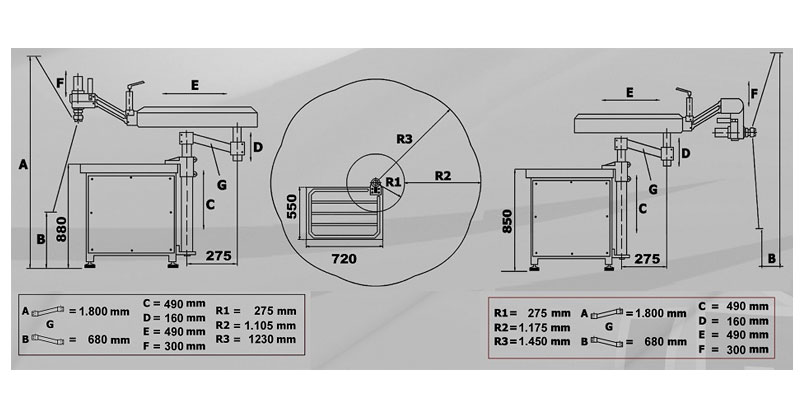

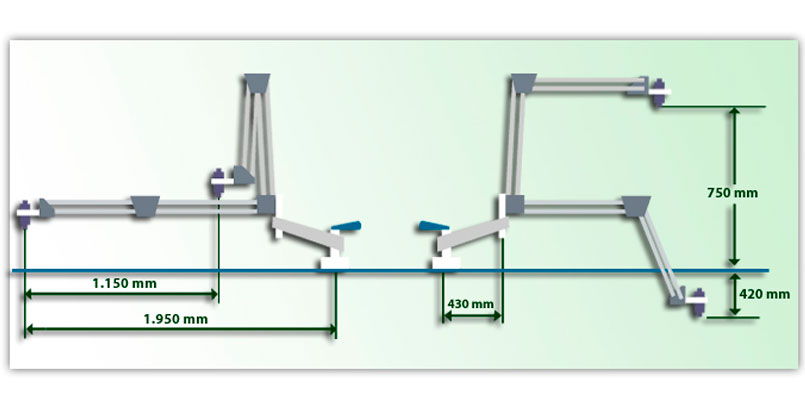

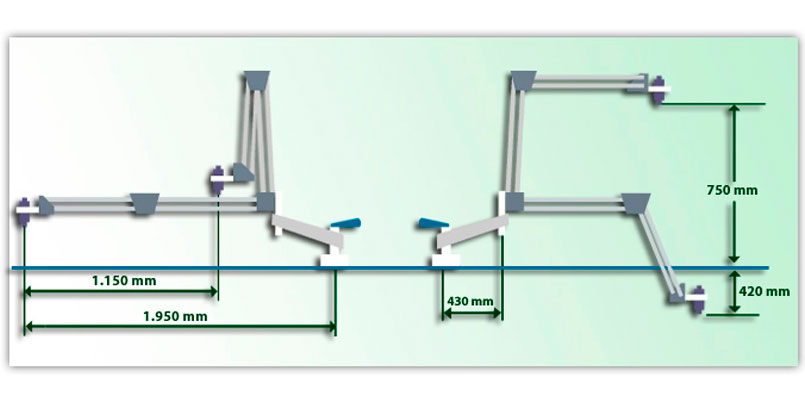

HYDRAULIC TAPPING MACHINE MT-M39 THREADING CAPACITY:

HYDRAULIC TAPPING MACHINE MT-M39 THREADING CAPACITY:This model is specially indicated for large productions of vertical and horizontal tapping, accurate mechanics, moulds and / or parts requiring a high accuracy in the execution of the tapping, with a full quality guarantee both in the finish and tapping tolerances.The machine head allows to place standard tool directly up to measures of 30 mm. It is necessary to work with a special chuck adapter from Gamor for bigger sizes. This special tap-holder fits in the chuck machine and can be used for sizes up to 36×29 mm.

-

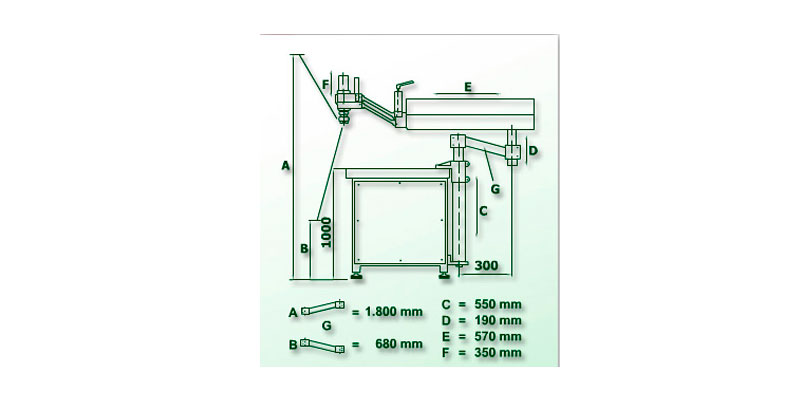

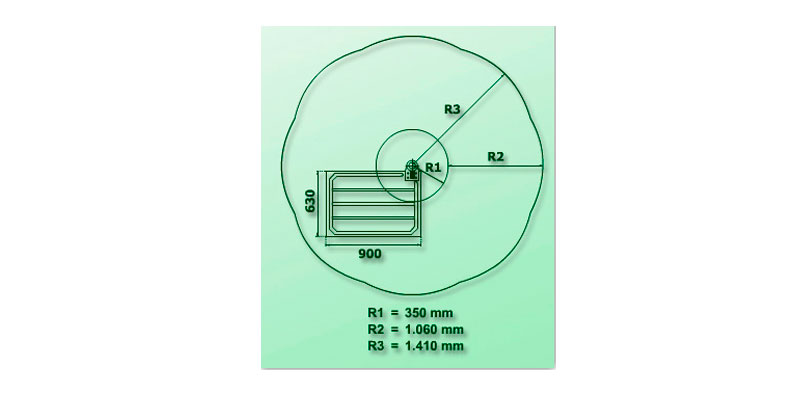

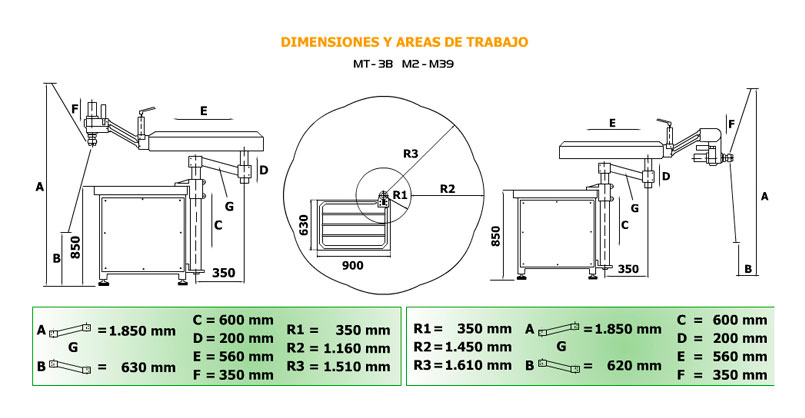

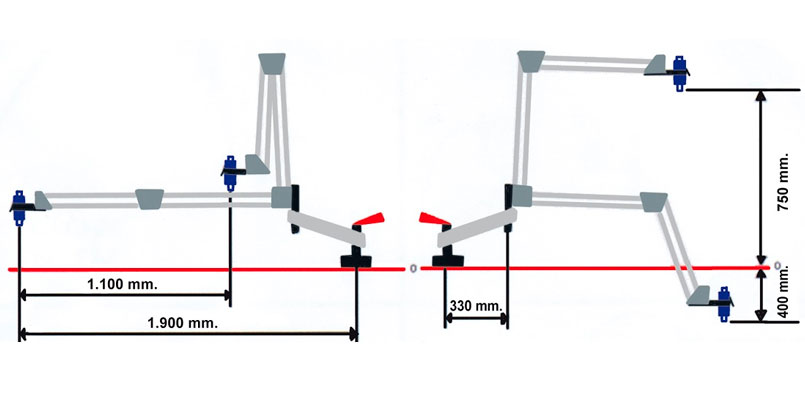

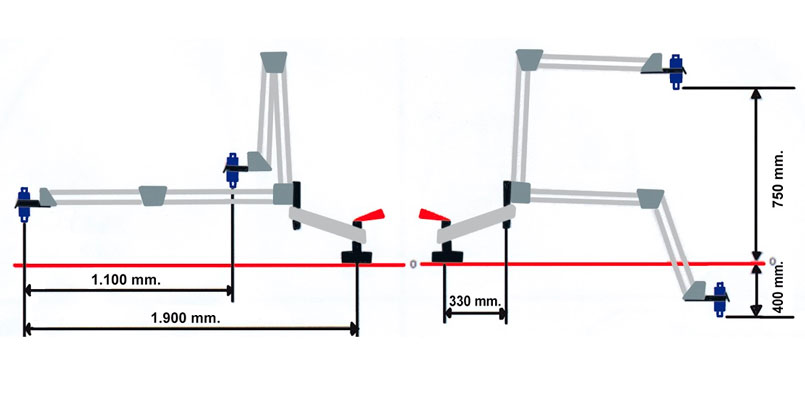

GAMOR HYDRAULIC TAPPING MACHINE M2-M36

GAMOR HYDRAULIC TAPPING MACHINE M2-M36THREADING CAPACITY:

This model is specially indicated for large productions of vertical tapping, accurate mechanics, moulds and/or parts requiring a high accuracy in the execution of the tapping, with a full quality guarantee both in the finish and tapping tolerances. The machine head allows to place standard tool directly up to measures of 30 mm. It is necessary to work with a special chuck adapter from Gamor for bigger size. This special tap-holder fits in the chuck machine and can be used for sizes up to 36×29 mm.

TELEPHONE: +34 943 69 10 99 | E-MAIL: gamor@gamor.es